Schock resolves thermal bridging and fire resistance issues in Dublin

Work is under way on the €15 million redevelopment of Father Scully House in the centre of Dublin. The investment consists of two linked buildings, one five-storey, the other seven, and will result in 99 apartments and other communal facilities that provide affordable accommodation for older people, many with limited mobility.

The new Father Scully House is on the site of the original building in Gardiner Street, which is a busy area of the city. To provide a more tranquil outlook, the residential apartments are planned around an expansive internal courtyard with generous balconies opening onto a central garden.

The overall design is high specification, and two critical considerations at the balcony connectivity areas are the prevention of thermal bridging and improved fire resistance. With thermal bridging, there is a regulatory need for a major reduction in local heat loss and CO2 emissions. However, condensation is a likely problem too, which can lead to structural integrity problems and worse, it encourages mould growth. For the elderly residents at Father Scully House, this could have serious medical implications in the form of possible respiratory problems and dermatitis.

The most sophisticated solution for the prevention of thermal bridging, in connective situations, is the market leading Isokorb thermal break module from Schöck. It offers outstanding thermal efficiency and unrivalled application options, allowing connections to be made between concrete-to-concrete, concrete-to-steel and steel-to-steel. One of the modular connection types even allows the retro-fitting of balconies in certain situations. It is a range that comfortably exceeds the requirements of BRE IP1/06 and Part L, Irish Building Regulations, which stipulate that the temperature factor used to indicate condensation risk (fRSI), must be greater than, or equal to, 0.75 for dwellings, residential buildings and public buildings. All products provide BBA Certification and LABC Registration, and are supplied by the Schöck sales partner and sole distributor for the whole of Ireland, Contech Accessories, of Tullow, County Carlow.

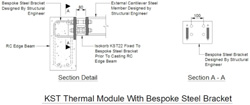

For the new Father Scully House project it is primarily the type K Isokorb and the type KST Isokorb that have been incorporated. Type K provides a thermal break between external reinforced concrete components and the building, reducing thermal losses to a minimum, by virtue of innovative technology involving HTE module compression bearings. The type KST allows thermal breaks to be incorporated into steel-to-steel connections and is a modular system that can be used for connections involving all profile sizes and structural loads. On this occasion it is attached to a bespoke steel bracket and then cast-in to a concrete edge beam, ready for the external steel section (see diagram).

In addition the Schöck Isokorb type W is incorporated into the project as well, where there is a demand for thermal insulation of storey height wall elements. Because of the safety requirements in terms of the fire resistance class of the balconies, the Schöck units have been supplied to fire resistance class F90. If specified, it is also possible to provide certain units with an F120 rating.

The project is funded mainly by the Department of the Environment for the Catholic Housing Aid Society – which was set up by a small group of individuals, including, Father Tom Scully – a key figure in the development of the original eponymous building back in 1966. This was in response to a building collapse in Dublin which resulted in many elderly people losing their lives. The founding members recognised the vulnerability of this group and decided to build apartments for the aged poor. To date the Society has provided homes for 160 people, with various projects in progress, which will provide 300 units over the next two years.

For a free copy of the Schöck Specifiers Guide and /or full Technical Guide, contact Schöck Ltd on 01865 290 890 or visit http://www.schoeck.co.uk

Ends

Note to Editors

Schöck has grown to become Europe’s leading supplier of innovative structural load bearing insulation products. Its headquarters are at Baden-Baden in southern Germany and there are subsidiary companies in Great Britain, France, Austria, Switzerland, the Netherlands, Belgium, Poland, Italy and Hungary. Sales teams and partners operate in many other European countries and also Canada and the Middle East. Schöck is committed to providing the highest level of technical back up and comprehensive customer service to the construction industry.

Article supplied by Schöck Ltd