Permaban Company Profile

Permaban was established in 1983 and specialises in the manufacture of concrete floor protection products including

- Armoured joints which act as permanent formwork during the concrete pour and protect construction joints from impact damage once the building is in use;

- Leave-in-place formwork;

- Dowel systems for load transfer between concrete slabs;

- Surface hardeners (dry-shakes), which give the floor added impact and abrasion resistance;

- Concrete sealers, which control the curing of a concrete floor and give added protection to the surface.

Building in protection to concrete floors provides long-term cost savings, as it reduces the need for costly repairs to the floor in years to come, and prevents premature wear for materials handling equipment. Many products also speed the construction process, saving time on site for contractors.

Permaban’s products have been used in factories, warehouses, distribution centres and retail outlets for over 30 years. Its products, and strong commitment to service, have won the respect and trust of engineers, architects, building owners and contractors worldwide.

Permaban manufactures in the UK, and operates worldwide through a network of agents, distributors and partners.

The company is ISO9001 accredited, and creates bespoke solutions in addition to its comprehensive range of standard products. It is continually seeking to enhance and optimise its products, and has won industry awards for its product innovation.

Permaban is part of RCR Flooring Products, a division of the international specialist flooring group RCR Industrial Flooring.

Services

Permaban provides a range of services to assist clients in specifying the most appropriate solution for a particular application. The team of technical engineers can offer specific advice and guidance over the telephone and if necessary provide office or site visits. The website offers detailed information on regulations and standards and NBS specification clauses relating to the products. Educational and CPD-accredited seminars are also available.

The product range includes:

Armoured Joints

Armoured joints,also called leave-in-place joint systems, protect construction joints in concrete floors from impact damage. Armoured joints act as a permanent formwork and provide a secure boundary during a concrete pour. They enable a concrete slab to contract in a controlled manner, preventing cracks. The armoured joints also protect the joint arrises from impact damage (eg, from materials handling equipment) once the building is in use. Integral dowels offer effective load transfer between concrete slabs, providing stability and durability. Options include:

- AlphaJoint: The original market-leading armoured joint, available in three versions

- AlphaSlide: Developed for large bay jointless concrete floors and for wider joint openings

- BetaJoint: A tough and lightweight formwork and armoured joint system for floors and pavements

- Signature: An award-winning half-hexagon shaped armoured joint which prevents impact damage

- Eclipse: A hard-working, versatile joint for heavy-duty applications; its clever design incorporates reinforcement where it is most needed.

- StripJoint: StripJoint is a heavy duty joint armouring for timber formwork applications.

PermaSteel Leave-in-Place Formwork

PermaSteel screed rail leave-in-place formwork has been developed to contain a concrete pour. The formwork is extremely simple to install and is available in various sizes and styles to suit the majority of slab depths. PermaSteel is supplied in galvanised steel for weather resistance and is suitable for external slabs and pedestrian use.

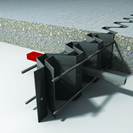

Dowel Systems

Dowel systems are specified for providing load transfer between adjacent concrete slabs and to control movement of slabs whilst curing. Concrete slabs have 50% of their load-bearing capacity at the edges and dowels are therefore required to provide support. Diamond plate dowels are fast and simple to install and are a cost-effective option. PermaSleeve square dowel bars provide improved resistance to bending and shear while allowing for two-way lateral movement of the slab. TD dowels are an easy-to-install trapezoidal dowel plate which provides superior load-bearing and resistance to bending and shear.

Surface Hardeners

Surface hardeners - often called dry-shake toppings - offer a range of benefits including durability, slip and abrasion resistance, and colour. Permaban supplies the highly-respected Rocland brand, known worldwide for its ease of application, wide colour range, and high-quality results. Surface hardeners can be applied to freshly-laid concrete as a “dry-on-wet” powder; or as a “wet-on-wet” slurry for a superior finish and extra durability.

Concrete Sealing and Curing

The concrete sealing and curing range of spray-on additives assists floors in curing quickly in a controlled manner. The sealing and curing products partially seal the concrete floor’s surface, providing protection and increasing the floor’s hardness and durability. AquaCure PUA is a water-based product which combines polyurethane and acrylic and is a low VOC product. PermaSeal is a solvent-based acrylic resin which forms a curing membrane and impregnates the concrete to seal and protect it. Both products can be used for new and existing concrete floors.

Joint sealants

The PermaFlex range of joint sealants fills gaps in saw-induced and formed construction joints, to halt joint arris damage and prevent debris from entering the joint. Joint sealants are also used for preventing health and safety hazards such as shoe heels catching in joints. There are six options available for saw-cut joints and gaps in armoured joints which come in a variety of hardness and temperature performance ranges.